|

|

|

Engineering & Design

Our designs are based on well known international standards such as DIN, BS, ASME, or others as requested by our clients.

atea’s multinational engineering team consists of experienced engineers covering all engineering disciplines necessary to build dual laminate equipments such as vessels, tanks and process piping.

Engineering capabilities include:

• Stress analysis and static calculations for vessels, tanks and pipes.

• Design work via 3D-CAD, including isometric drawings.

• Project and construction management, both for basic and detailed designs.

Our designs are very flexible, depending on the application of the finished product.

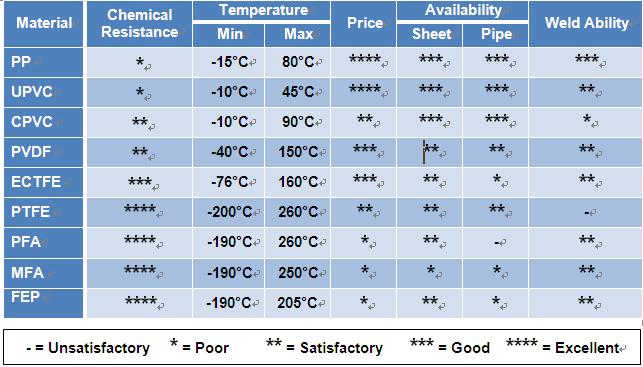

A wide range of different thermoplastic and FRP combinations can be selected. Our engineers base the material selection on their experience, cost factors and environmental influences such as temperature, pressure and pH in order to guarantee best possible value for money.

Conductive properties can be tailored into the design of dual laminate products through the use of conductive thermoplastics as in-liner and conductive FRP as reinforcement.

More resistant thermoplastics will be used as in-liner in more demanding environments e.g. where strong chemicals are present and/or the temperature is high.

|

|

|